Packaging Printing Structural Design

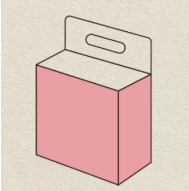

Step 1: Determine Structure & Dimensions

First, based on the product shape and shipping needs, decide the box type (e.g., top-bottom box, drawer box, folding box). Then, define the exact unfolded size, folding angles, and assembly logic for the packaging printing production process.

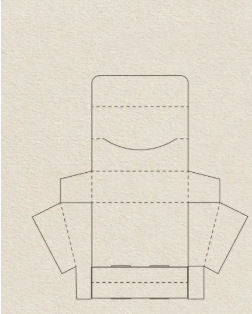

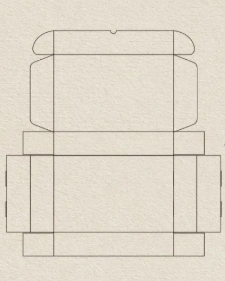

Step 2: Create the Die-Cut Template

Next, draw the vector outline of the packaging flat layout, including cut lines, fold lines, and glue tabs. Also, mark key dimensions (like height, width, and tab length) and account for material thickness in the packaging printing process.

Step 3: Add Bleed & Registration Marks

After that, leave a 3mm bleed area around the design to avoid white edges after cutting. Then, add trim marks and registration lines to ensure precise printing and die-cutting during the production process.

Packaging Printing Visual Design

Step 1: Layout & Graphics

Now, adapt the visual content to fit the die-cut template. Keep important info away from cut edges (add a safe zone) in the packaging printing production process.

Step 2: Prepare Print-Ready Files

For smooth production, save files in print-friendly formats (PDF, AI, EPS), embed fonts, and convert text to outlines. Also, make sure images are 300dpi or higher and in CMYK or spot color mode.

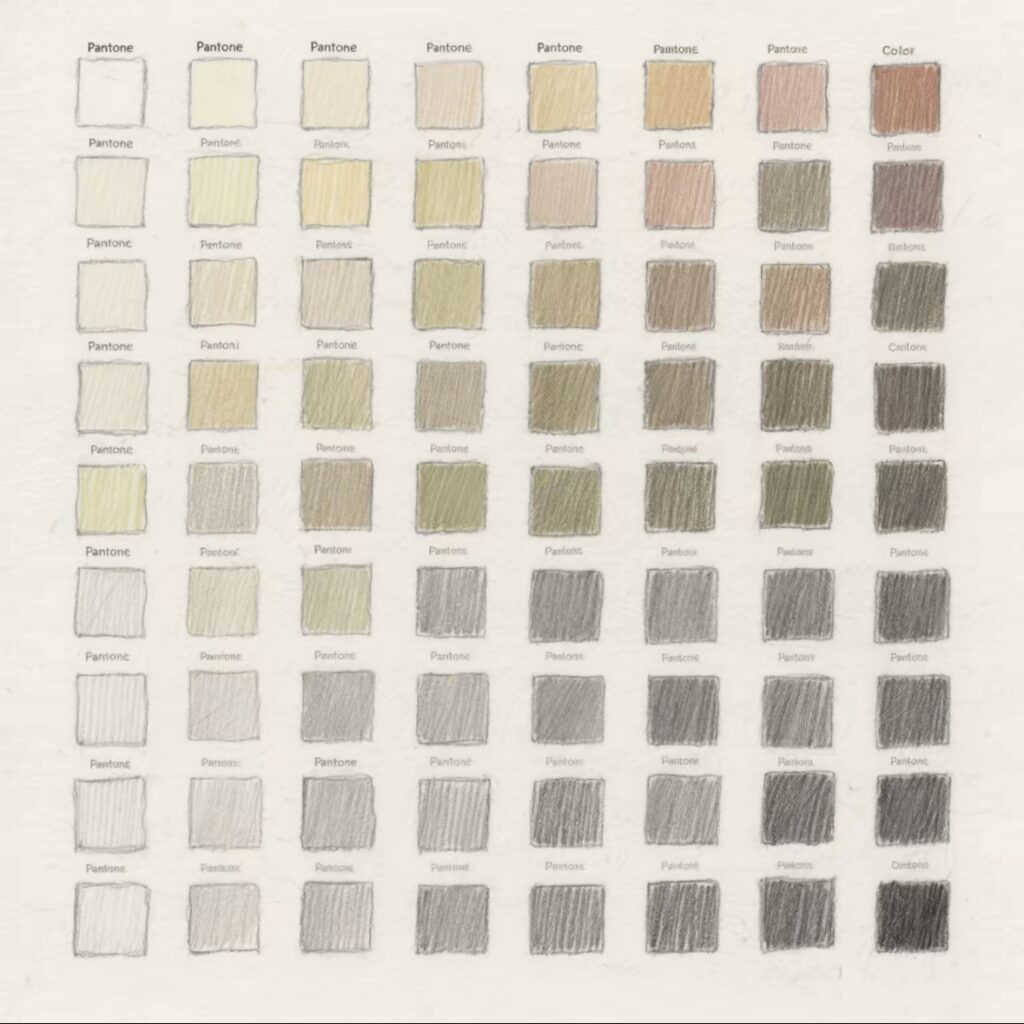

Step 3: Color Management & Notes

Clearly label Pantone colors (e.g., Pantone 185C) and mark special effects (foil stamping, UV coating, embossing) with samples or sketches as part of the production process.

Step 4: Color Separation

For standard printing, separate colors into CMYK channels. For special inks (like metallic gold), create separate spot color files essential to the packaging printing production process.

Packaging Printing Production

Step 1: Choose Materials

Depending on needs, pick paper types (white cardstock, corrugated, specialty paper) or plastics. Confirm weight, thickness, and surface finishes (like lamination or coating).

Step 2: Select Printing Method

- Offset Printing: Best for large orders with complex colors.

- Screen Printing: Used for bold colors or unusual materials (e.g., glass, fabric).

- Digital Printing: Good for small batches and custom designs.

Step 3: Post-Printing Finishing

- Surface Treatments: Matte/gloss lamination, UV spot gloss, foil stamping.

- Shaping: Die-cutting (follows the template), embossing, debossing.

- Assembly & QC: Gluing, folding, and checking print alignment, finishes, and stability.

Key Collaboration Tips

Step 1: File Handover Rules

Designers must provide: die-cut templates (AI/CDR), print-ready files (with bleed), and a finishing instructions sheet concerned with the packaging printing production process. Manufacturers should confirm: material samples and feasibility.

Step 2: Proof Approval

Before mass production, test a blank sample (for structure) and a color proof (for print/effects).

Step 3: Avoid Miscommunication

- Never describe finishes verbally—always write them down!

- Test ink adhesion on tricky materials (e.g., silk paper) first—or risk wasted prints!

Pro Tip:

For luxury gift boxes:

- Designer sends die-cut template → Factory makes blank sample → Adjust tab sizes.

- Designer finalizes foil + UV artwork → Printer makes color proof for approval.

- Mass production: Offset print on cardstock + antique gold foil + matte lamination + auto die-cutting in the packaging printing production process.