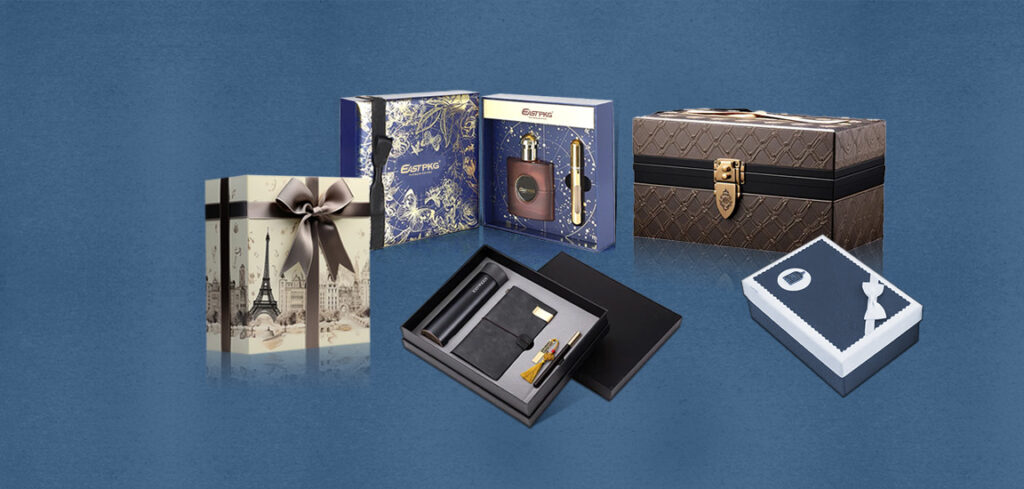

In high-end markets where premium goods, luxury items, precision instruments, and electronics dominate, rigid box packaging stands out as the choice for its durability, sophisticated appearance, and unparalleled protective qualities. Serving as more than just a container, the luxury rigid box functions as a powerful link between brands and consumers, blending utility with aesthetics.

This expert handbook provides a comprehensive guide for designers, manufacturers, and retailers to excel in a competitive market, enhance brand image, and protect product value with custom rigid box solutions.

Overview of Rigid Box Packaging

Rigid packaging boxes are more than protective shells—they are an extension of the brand, serving as a powerful storytelling tool. From material selection to structural design, every detail in a custom rigid box is meticulously crafted to deliver protection, presentation, and value enhancement. Each rigid gift box tells a unique brand story, making it an excellent investment for brands seeking to stand out in the marketplace.

In-Depth Analysis of Materials

The choice of materials plays a critical role in defining the quality and appearance of a rigid box. Each type of material offers distinct advantages for specific applications, making it essential to choose the right one to meet both practical and aesthetic goals.

- Cardboard. A preferred material in the creation of eco-friendly rigid boxes, cardboard is both sustainable and cost-effective. Not only is it recyclable, but it also adapts to various design requirements, allowing rigid box manufacturers to create both minimalistic and intricate visuals through advanced printing techniques. This versatility makes cardboard a leading choice for custom rigid box solutions that need to balance environmental concerns with aesthetic appeal.

- Plastic. With excellent water and moisture resistance, plastic is often used in rigid packaging boxes that require visibility, such as transparent display boxes. While plastic’s durability is ideal for certain products, many rigid box manufacturers are now prioritizing eco-friendly plastic options to minimize environmental impact and meet the growing demand for eco-friendly rigid box alternatives.

- Composite Materials. Combining the strengths of multiple materials, composites expand the design possibilities of rigid packaging boxes. Offering both practicality and visual appeal, composites are an innovative solution for brands that require both aesthetic sophistication and robust functionality.

- Metal. Metal materials elevate the appeal of luxury rigid boxes with their corrosion resistance and durable properties. Known for creating a high-end feel, metal is frequently used in packaging for premium goods. While more costly, its aesthetic and functional qualities make metal an attractive choice for custom rigid box designs aimed at creating an exclusive look and feel.

Endless Possibilities in Design and Creativity

Rigid box packaging offers ample room for creative expression, allowing brands to merge functionality with distinctive brand identity. Here are some essential design elements to consider:

1. Structural Design:

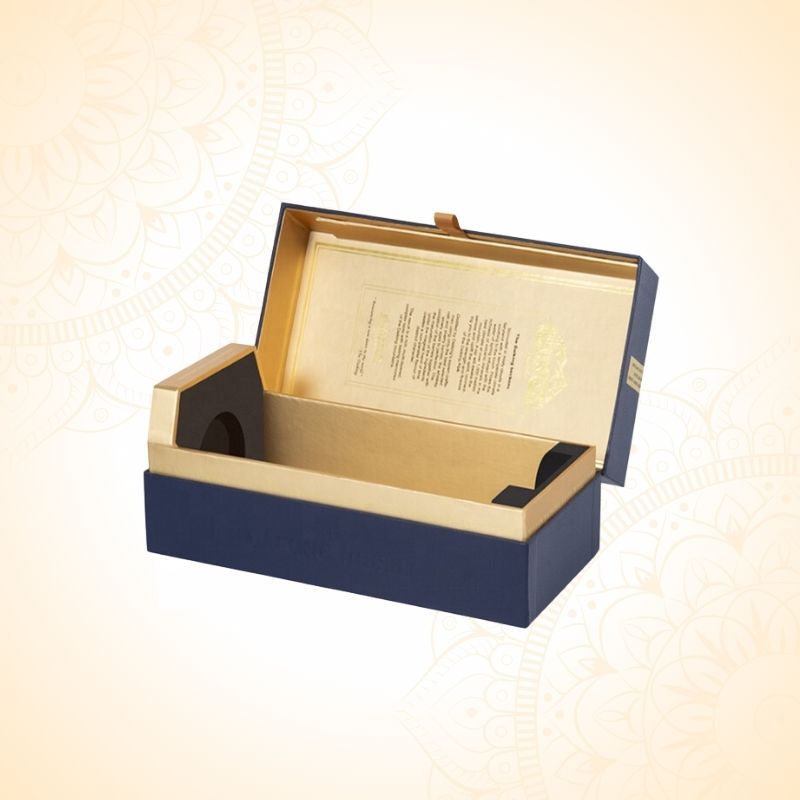

Careful structural design is vital for product stability. Rigid gift boxes are often crafted with user experience in mind, incorporating thoughtful opening mechanisms for added convenience. For example, a magnetic closure rigid box provides a satisfying “click” and secure closure, enhancing the unboxing experience for customers and reinforcing brand quality.

2. Aesthetic Design:

Integrate brand colors, patterns, and textures to create a visually appealing luxury rigid box. Every detail, from color choice to surface finish, should reflect the brand’s craftsmanship. By collaborating with a rigid box supplier, brands can ensure that each custom rigid box matches their visual identity and captivates consumers.

3. Personalized Customization:

Bespoke elements, such as engraving, embossing, and inlaying, add a personalized touch, elevating the box’s perceived value. Customization is key to creating a rigid gift box that resonates with customers, making it a keepsake while strengthening brand recall.

Key Points in Production and Quality Control

The production of high-quality rigid box packaging requires precision and adherence to stringent standards. Here are the core stages involved:

1. Mold Making

High-precision molds are foundational in creating rigid packaging boxes. Precise control over mold dimensions and quality lays the groundwork for subsequent processes, ensuring the custom rigid box meets the brand’s specifications.

2. Forming and Processing

Techniques such as stamping and injection molding are employed to form the rigid box with lid while maintaining strict control over temperature and pressure. This helps prevent material deformation, ensuring each rigid box maintains its shape and structural integrity.

3. Surface Treatment

Surface treatments, such as painting, plating, and polishing, enhance the luxury rigid box appearance while meeting safety and environmental standards. By incorporating these processes, rigid box manufacturers can achieve the desired aesthetic while ensuring high durability and quality.

4. Assembly and Inspection

Every rigid gift box is carefully assembled and rigorously inspected to meet quality standards. Through meticulous quality checks, manufacturers can guarantee that the final product aligns with the brand’s promise of durability and sophistication.

The Path to Environmental Sustainability

As sustainability gains prominence, rigid box manufacturers are increasingly adopting eco-friendly materials, optimized designs, and focusing on recyclability and reusability. These efforts lead to eco-friendly rigid boxes that satisfy environmentally conscious consumers, opening new market opportunities and supporting long-term growth in a sustainable direction.

Market Trends and Future Outlook

The future of rigid box packaging is marked by innovation and adaptability to meet growing demands. As e-commerce expands and consumers seek more personalized packaging, trends such as smart technology integration, biodegradable materials, and lightweight designs are shaping the future. Here are key trends to consider:

- Smart Technology Integration: Embedding NFC tags or QR codes into the rigid box for enhanced user engagement.

- Biodegradable Materials: As sustainability takes center stage, biodegradable materials are gaining traction, especially in eco-friendly rigid box solutions.

- Lightweight Designs: Utilizing innovative lightweight materials helps reduce shipping costs and aligns with environmental goals without sacrificing quality.

Embracing these trends enables brands to increase the value of their custom rigid boxes and improve customer engagement.

Conclusion

Rigid box packaging is a powerful bridge connecting brands and consumers. This handbook provides an in-depth exploration of luxury rigid box solutions, offering inspiration and guidance for your packaging design journey. By working with industry experts, rigid box suppliers, and embracing innovation, we can drive progress in the rigid box packaging industry, creating solutions that protect products, promote brand value, and contribute to a sustainable future.