In the ever-evolving modern world, flexible box packaging has become the preferred packaging solution for various industries, including food, personal care, pharmaceuticals, and electronics, thanks to its unique advantages—lightweight, flexibility, cost-effectiveness, and eco-friendly recyclability.

As a versatile solution, flexible packaging connects every link between production and consumption. This comprehensive guide aims to delve into every aspect of this crucial packaging form, highlighting its importance, current advancements, and future potential.

In-Depth Analysis of Flexible Packaging Materials

Choosing the right materials is key to balancing packaging performance, functionality, and cost-effectiveness. Here are some of the most widely used materials in flexible packaging:

1. Plastic Films

Commonly used materials like PE, PET, and PP are integral to flexible packaging for food and personal care products due to their lightweight, water resistance, and excellent airtightness. These materials are versatile in terms of thickness, transparency, and printability, making them ideal for custom applications. Flexible storage boxes made from durable plastic films are especially valuable for sensitive or delicate products.

2. Aluminum Foil

With superior barrier properties against light, oxygen, and microorganisms, aluminum foil is widely used in high-end food and pharmaceutical packaging. It maintains product freshness, quality, and safety, extending shelf life and offering a premium feel. This material is also valuable in custom flexible box solutions where a high level of protection is needed.

3. Paper

As an eco-friendly and recyclable material, paper in flexible packaging offers a unique texture and natural aesthetic that appeals to environmentally conscious consumers. When combined with modern printing techniques, paper packaging becomes highly customizable and suitable for a wide range of markets, including food, cosmetics, and retail gift boxes.

4. Composite Materials

By combining multiple layers through lamination or co-extrusion, composite materials offer enhanced properties such as flexibility, durability, and resistance to external factors. This multi-layer structure meets complex packaging requirements, such as those for flexible corrugated boxes, which need to be both lightweight and protective.

Design Principles and Aesthetic Considerations

Effective design in flexible packaging combines functional protection with visual appeal to create a memorable brand experience. Here are the core principles that guide the design of flexible packaging boxes:

1. Protection Principle

Packaging must be durable enough to withstand impacts during transit and prevent damage to the product, ensuring it reaches consumers in perfect condition. This is particularly important for fragile or delicate items where packaging failure could lead to significant financial and reputational losses.

2. Convenience Principle

Flexible packaging should be designed for easy handling, storage, and usage. Features like easy-tear openings, resealable closures, and compact folding options help enhance user experience. Flexible folding boxes are particularly advantageous for their compact storage potential and ease of use.

3. Aesthetics Principle

Packaging that incorporates visually appealing designs, colors, and patterns can greatly enhance brand recognition and consumer appeal. Aesthetics play a significant role in influencing purchasing decisions, as consumers are naturally drawn to attractive and unique packaging that reflects the brand’s identity.

4. Environmental Principle

Eco-friendly materials and minimalistic designs are increasingly preferred, reflecting a growing trend towards sustainability. Many brands choose eco-friendly flexible boxes that are recyclable, biodegradable, or made from renewable resources, helping to reduce environmental impact.

Production Processes and Cutting-Edge Technologies

Flexible packaging production involves advanced technologies that ensure efficiency, precision, and quality:

1. Printing Technologies

Techniques like rotogravure, flexographic, and digital printing enable high-resolution, vibrant packaging designs that enhance brand visibility. Digital printing, in particular, offers flexible and cost-effective solutions for small batch runs, supporting customization and rapid response to market changes.

2. Lamination Technologies

Eco-friendly lamination methods, such as solventless lamination, help secure a strong bond between multiple material layers, ensuring durability and enhancing barrier properties. Lamination not only strengthens the packaging but also provides a glossy or matte finish for visual appeal.

3. Bag-Making Technologies

Advanced equipment enables precise cutting, sealing, and shaping of packaging to fit different products. Heat sealing and ultrasonic sealing are common methods, providing durable and airtight seals to maintain product integrity and freshness.

Market Trends and Future Outlook

Driven by consumer demand and regulatory shifts, the flexible packaging industry is witnessing significant transformations:

1. Environmental Focus

The increasing emphasis on sustainability is pushing brands to adopt recyclable and biodegradable materials. This includes using bio-based plastics and plant-derived materials in eco-friendly flexible boxes to meet consumer demand for greener options.

2. Smart Technology Integration

With the advent of IoT, flexible packaging is evolving to incorporate smart features like RFID tags, QR codes, and sensors that allow tracking, anti-counterfeiting, and real-time monitoring of product conditions. These technologies enhance transparency and trust, as consumers can verify product authenticity and freshness.

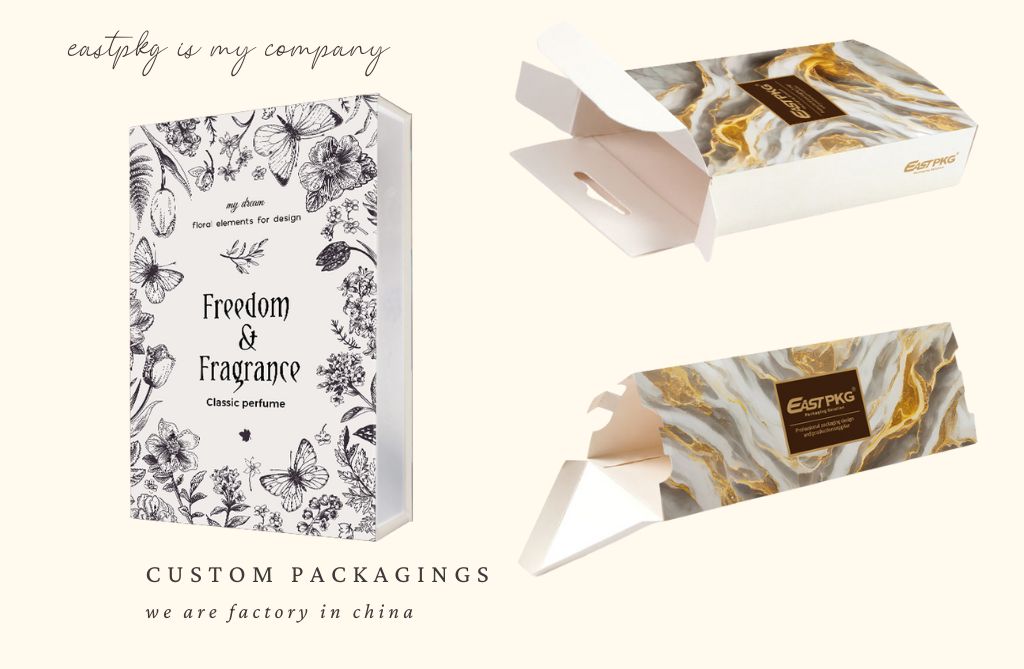

3. Customization and Personalization

Custom flexible boxes are gaining popularity as brands aim to create unique and memorable consumer experiences. Personalized packaging allows companies to differentiate themselves, appeal to niche markets, and build stronger brand loyalty.

4. Lightweighting Initiatives

As companies seek to reduce transportation costs and emissions, flexible packaging designs are becoming increasingly lightweight without compromising durability. Lightweight packaging aligns with global sustainability goals by reducing resource use, energy consumption, and carbon emissions.

Environmental Considerations and Sustainable Development Strategies

In light of growing environmental concerns, the flexible packaging industry is working to adopt sustainable practices that contribute to a circular economy:

1. Promoting Eco-Friendly Materials

By choosing recyclable, compostable, and biodegradable materials, brands are reducing their reliance on traditional plastics. Options like recycled PET and bio-based PE are being widely adopted in flexible box packaging.

2. Optimizing Packaging Design

Minimalistic packaging designs that use fewer materials and eliminate unnecessary layers help reduce waste. Sustainable packaging innovations focus on designing for reusability and recyclability, helping to limit resource consumption.

3. Implementing Recycling Systems

Establishing efficient recycling channels and encouraging consumers to recycle packaging play a critical role in supporting a circular economy. Packaging companies are collaborating with recycling facilities to ensure that flexible packaging waste can be efficiently processed.

4. Educating Consumers

Many brands are raising consumer awareness about sustainable practices, including proper disposal and recycling of packaging materials. This education effort empowers consumers to make informed choices and adopt eco-friendly habits.

Conclusion

As a vital component of the modern packaging industry, flexible packaging offers innovative solutions that cater to dynamic consumer needs and evolving environmental concerns. With ongoing advancements in material science, printing, and sustainable design, flexible box packaging is poised to remain a popular choice for brands looking to combine functionality with a positive environmental impact. Custom flexible boxes and eco-conscious designs play an instrumental role in the future of packaging, providing solutions that are safer, more convenient, and visually appealing.

The future of flexible packaging will undoubtedly see further integration of technology, sustainability, and consumer-centric design. With these changes, the industry is well-positioned to contribute to a more sustainable, efficient, and responsible global economy. Flexible packaging is not just about containing products; it’s about shaping a future that values innovation, environmental stewardship, and customer satisfaction. Through collaborative industry efforts, flexible packaging is poised to lead the way in creating a greener and more efficient packaging world.