In the fields of art creation and design, color serves as both the heart of visual impact and a powerful means of conveying emotions and information. When it comes to mass-producing artwork on custom paper boxes, choosing the right printing technology is crucial for achieving the desired aesthetic and branding impact.

Spot color printing (Pantone) and process color printing (CMYK) are two primary printing methods in the industry, each offering unique artistic value and application potential. This article delves into the essence of these two techniques, guiding you to make the best choice for your custom packaging.

The Twins of the Color World: Spot Color Printing vs. Process Color Printing

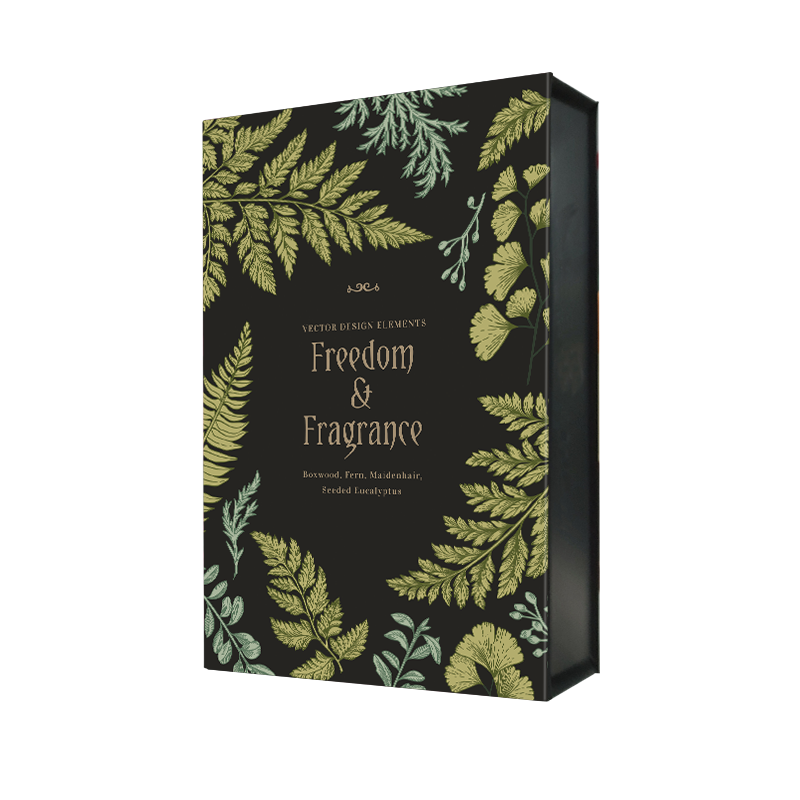

- Spot Color Printing (Pantone): Known for its precision, spot color printing uses pre-mixed inks of specific colors. The Pantone Matching System (PMS) provides a vast, universally recognized color library with precise definitions, ensuring consistency across print runs. This level of accuracy makes it ideal for custom paper boxes that incorporate corporate brand colors or feature large, solid color areas. However, it’s important to note that Pantone colors may vary slightly depending on the material used, so previewing is crucial, especially for premium or luxury packaging boxes.

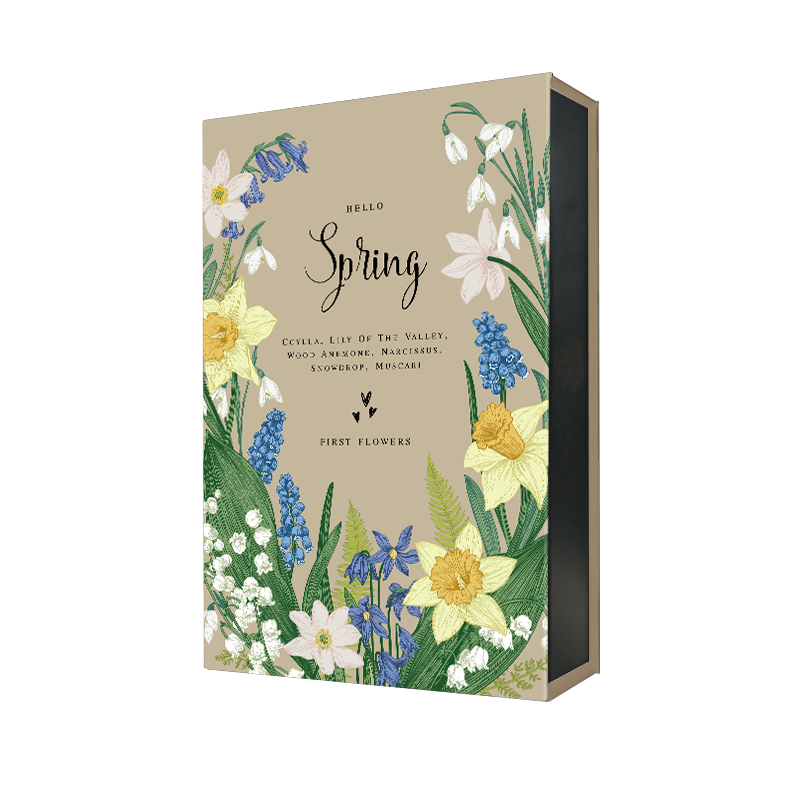

- Process Color Printing (CMYK): Process color printing combines Cyan, Magenta, Yellow, and Black inks to produce a broad color range, suitable for reproducing images and photographs. Known for flexibility and cost-effectiveness, CMYK printing can recreate natural colors and subtle gradients, making it ideal for detailed images on custom printed boxes. However, certain high-saturation or metallic colors may be challenging to achieve with CMYK, where spot color printing could provide a better match.

Choosing the Right Printing Method for Your Custom Paper Box Design

- Brand Color Requirements: If you’re printing custom packaging boxes that strictly adhere to brand colors or have extensive solid color coverage, spot color printing ensures brand consistency and a professional look. This option is also ideal for eco-friendly packaging with minimal designs, where a few high-quality colors convey a strong brand message.

- Image Content: For custom boxes featuring complex images, layered effects, or blended colors, CMYK printing is usually more efficient and cost-effective. This method is well-suited to designs that prioritize color depth and vibrancy, offering rich, varied results that enhance the visual appeal of the packaging.

- Cost Considerations: Spot color printing may incur higher costs due to the use of custom inks and additional setup, especially for small orders. Process color printing is typically more budget-friendly, using standardized inks that work well for high-volume runs. For wholesale custom packaging or large-scale orders, the cost-effectiveness of CMYK makes it an attractive choice, especially for brands aiming to balance quality with budget.

Bridging Prototypes and Mass Production

During the prototype stage, digital CMYK printing is often used to quickly assess the artwork’s look and layout on custom cardboard boxes or folding carton packaging. This helps clients make adjustments before full-scale production. However, colors on prototypes may differ from the final result, particularly for Pantone shades. For projects where precise color matching is crucial—such as custom packaging boxes for luxury products—it’s advisable to produce offset printing samples for the final review.

The Artistic Splendor of Mass Production: The Charm of Offset Printing

Once prototypes are approved, mass production shifts to offset printing, known for superior print quality and production efficiency, making it the preferred choice for high-end custom boxes. Offset printing ensures each color is transferred accurately, using individual stations and ink plates, which is essential for achieving uniformity across large runs. For designs requiring high detail or vibrant colors, offset printing on custom paper boxes brings out rich textures and intricate details, elevating both product appeal and brand impact.

Practical Tips and Techniques for Custom Paper Box Printing

- Color Preview: When using Pantone colors on branded packaging boxes, preview colors on various substrates to understand any possible variations. Material texture and surface treatment can affect how colors appear, so this step helps make informed adjustments.

- Color Management: Consider color matching tolerances and the impact of substrate textures, finishes, and lighting. For custom paper boxes with logos, think about how different finishes (such as matte or gloss) may alter color perception and make adjustments as needed.

- Design Optimization: Spot color designs are best submitted in vector format, which avoids issues with transparency or gradients and simplifies the printing process. Vector designs ensure that custom printed boxes maintain color accuracy and quality across each print run.

- Physical Samples: Providing physical samples, especially for luxury packaging or eco-friendly packaging boxes, allows for a more accurate preview of the final product. Samples enable you to ensure alignment with design goals, reducing the risk of color discrepancies.

Environmental and Economic Advantages of Using Custom Paper Boxes

In addition to enhancing aesthetics, custom paper boxes offer substantial environmental benefits. Crafted from recyclable, biodegradable materials, paper boxes meet today’s demands for sustainable packaging that aligns with green initiatives

- Reduced Environmental Impact: Custom paper boxes are eco-friendly and support a circular economy. They allow businesses to minimize waste and reduce environmental impact through materials that are recyclable and biodegradable.

- Cost-Efficiency for Bulk Orders: Wholesale custom paper boxes are cost-effective for large-scale production without sacrificing quality. Offset printing in bulk enables businesses to achieve high-quality results with lower per-unit costs, making it an economical choice.

Conclusion

Spot color printing and process color printing each bring unique advantages to custom paper boxes, allowing brands to choose the best option based on their aesthetic, financial, and operational needs. Understanding these two printing methods enables businesses to create customized packaging that stands out visually while strengthening brand identity. Whether prioritizing color precision, cost efficiency, or sustainability, each printing approach adds distinct value to the final packaging.

In a competitive market, custom paper box packaging serves as more than protection—it’s a representation of brand values and product quality. By carefully selecting the appropriate printing techniques, you can elevate product presentation, meet sustainability goals, and align with industry standards and consumer expectations. Choosing the right printing approach not only enhances the visual charm of your custom packaging but also adds lasting value to your brand.